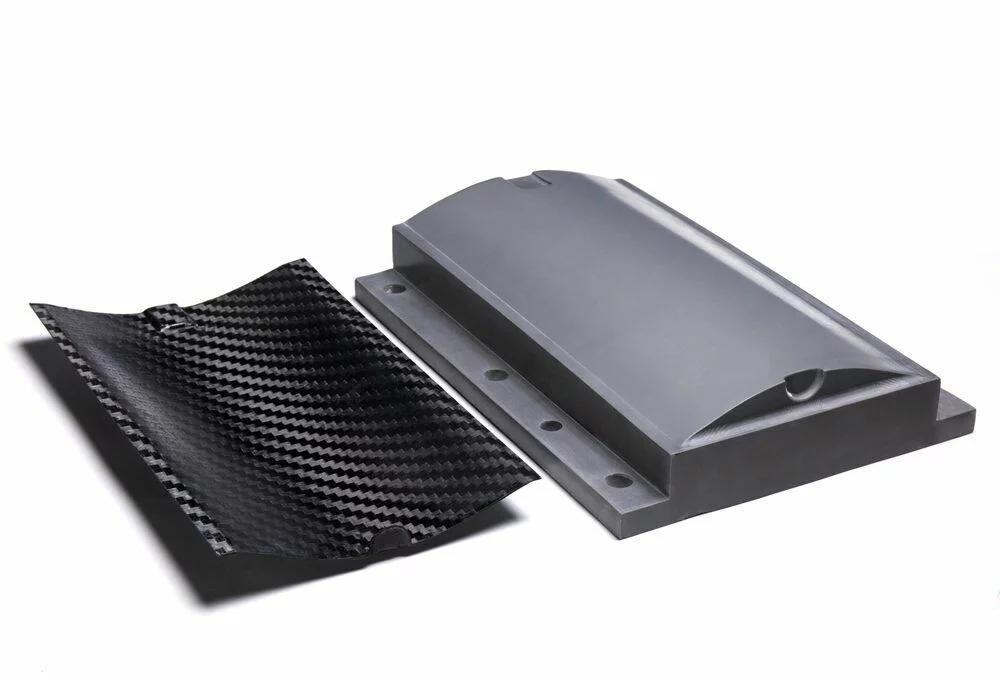

PRINT INDUSTRIAL MOLDS FOR COMPOSITES. FAST.

Massivit 10000 – 3D Industrial Printer

The Massivit 10000 additive manufacturing system is designed to overcome the bottlenecks of mold production for composite manufacturing. Find out how to digitally print industrial-grade, isotropic molds in 80% less time. For any complex design.

| Massivit 10000-G – transforming manufacturing of large partsThe Massivit 10000-G combines the full range of large-scale tooling applications available on the Massivit 10000 with extensive Gel Dispensing Printing applications for custom manufacturing and functional prototyping. |

Automate your mold productionConventional mold production processes – whether involving epoxy boards, plywood molds, or aluminum tooling – tend to be slow, costly, and reliant on manual labor. The Massivit 10000 brings digital transformation to the composite materials arena. Directly print industrial molds, thereby eliminating the need for a plug. |  |

| A range of large tooling applicationsPrint molds, master tools, jigs and fixtures for the automotive, marine, rail, defense, consumer goods, sporting goods, and construction industries. Produce open and closed custom molds for thermoforming, resin transfer molding (RTM), and reaction injection molding (RIM). |

World’s 1st isotropic, 3d-printed moldUnlike thermoplastic pellet and filament materials, Massivit’s epoxy-based casting material, CIM 500, offers fully cross-linked molecular bonds between casting intervals, delivering a true isotropic mold. CIM 500 also provides a high heat deflection temperature (HDT) and a low coefficient of thermal expansion (CTE). |  |