A warehouse management system (WMS) is defined as software designed to manage the movement of inventory to know where final products and goods are at any time to fulfill orders. A warehouse management system can be standalone software or part of an enterprise resource planning (ERP) system working with other integrated modules such as accounting, order management, inventory management, MRP, customer relationship management (CRM), and more using one central system and data source.

What Does a Warehouse Management System Do?

The purpose of a warehouse management system is to help organizations have an efficient warehouse by determining the best arrangement for storage and workflow. It tracks all forms of inventory so items can be quickly located and it helps to manage the supply chain by keeping track of what is needed and when. It supports the use of RFID tags, barcoding, and serial numbers. WMS software can even eliminate the need for periodic manual inventory counts.

WMS software improves warehouse processes by providing organized methods for receiving, picking, putaway, and shipment of goods that helps to reduce errors and improve employee satisfaction. It also can communicate with other departments like customer service so they can be informed of what is happening with orders in real-time to better assist customers. With automated processes and greater communication, a warehouse management solution decreases costs, improves productivity, and enhances service.

What Is the Role of a Warehouse Management System?

The role of a warehouse management system is to hold all of the material used or produced in manufacturing, from raw materials to finished goods, to ensure they efficiently move through the warehouse and are ready to be used as needed. It is becoming more important these days as same-day delivery, integrated logistics, and e-commerce has become more prominent.

What Is the Difference Between a Warehouse Management System and an Inventory Management System?

A Warehouse Management System keeps track of the storage and movement of items in a warehouse or distribution center. It also helps to ensure items are stored in the most efficient location and the correct items are picked and packed. WMS software also helps to manage all of the labor operations in the warehouse and monitor employee performance.

Inventory management systems help track inventory on hand, including raw materials, work in progress (WIP), final goods, and components needed to manufacture final goods. They keep track of stock levels and inform businesses if and when to produce more final goods and when materials and components are needed to manufacture a product. It provides information on how much of a specific item is available, whereas a warehouse management system tells you exactly where those items are within the warehouse right down to the bin it’s located in.

The biggest difference between the two systems is warehouse management systems help manage the work of employees in the warehouse, and inventory management only deals with stock and finished goods. Warehouse management systems are therefore typically more complex than inventory management systems.

Why Is a Warehouse Management System Needed?

With WMS software in place, running a warehouse and distribution center is much easier as it provides step-by-step guidance and verifies processes are being done correctly at each step. It can take away human error from a paper-based approach to improve efficiency, increase the speed of shipping and delivery, and improve the quality of customer service. It provides immediate insight into what is happening within the warehouse and historical information based on tracked data to understand trends and demand. Companies using a warehouse management system can be more competitive, provide a better customer experience, keep up with constantly changing demand, and optimize their supply chain.

Who Needs a Warehouse Management System?

If you have a warehouse or a distribution center and you want to be competitive, you need a warehouse management system. It is not effective to rely on a manual paper-based approach. You risk losing customers if you can’t execute well.

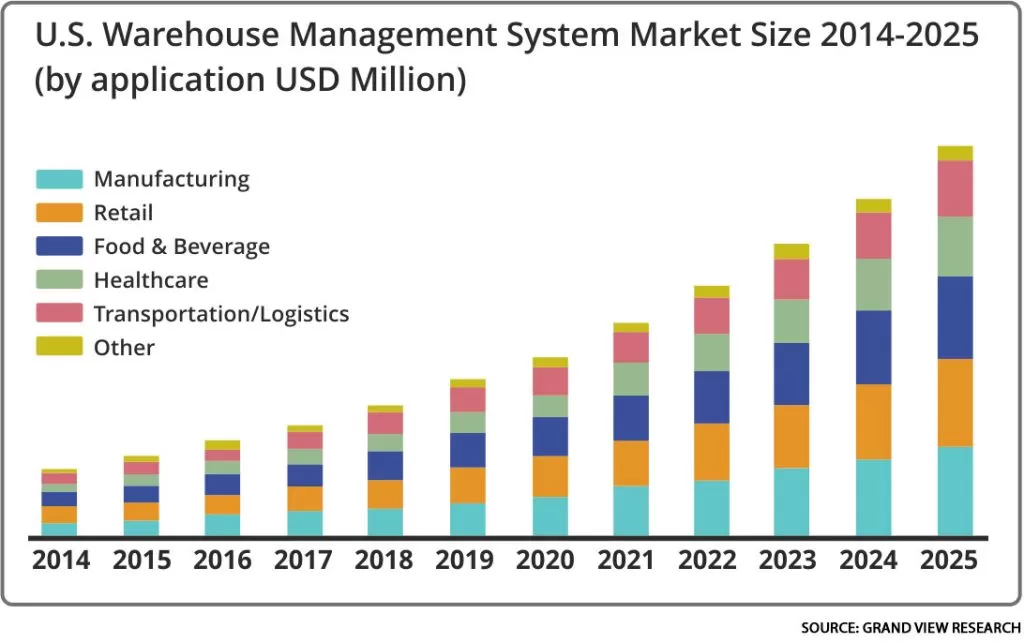

Many industries use WMS software, but six industries are the biggest users.Manufacturingcompanies need a warehouse management system to track multiple types of inventory, from raw materials to finished products.Retailfirms need a warehouse management system to help with the increase in online purchases so their customers can see inventory at their brick and mortar store locations and arrange for pick up or delivery.Food and BeverageandHealthcareboth need WMS software to accommodate the special needs of products that can spoil or expire to ensure they are kept in a suitable location and are shipped timely.Third-party Logistics (3PL)manage stock for multiple companies so WMS software is important to these businesses to ensure customers’ products are kept separate and managed independently.Wholesale Distributorshave large quantities of inventory to move so a WMS helps them streamline to keep labor costs down.

5 Signs You’re Ready for WMS

What Are the Benefits of a Warehouse Management System?

| Optimize Processes Streamline inbound and outbound processes, automate manual and paper-based processes such as inventory tracking and labeling, create more efficient warehouse routes, improve warehouse layout, and prioritize goals for more efficient operations. | Reduce Expenses Lower labor costs by speeding time to find items, reduce waste of premium floor space with a better layout, automate processes for fewer errors, and increase inventory visibility to reduce storage needs. | Improve Customer Experience Greater customer satisfaction from reduced mistakes, faster delivery times, and improved order status, and better vendor relations from quicker delivery approvals, and increased supply orders. |

| Optimize Supply Chain Improved efficiency and visibility in the warehouse also help to optimize the supply chain with faster processes and better demand planning. | Increase Inventory Visibility Real-time data, status, and tracking of inventory through barcoding, serial numbers, and RFID tagging to track its movement throughout the warehouse to keep stock at optimal levels. | Improve Labor Management Labor forecasting and KPIs to identify when staff is needed and how to optimize staffing and shifts to more efficiently create schedules and assign tasks. |

| Improve Employee Morale With automated processes, increased data and visibility, and more efficient task assignments, employees can provide more value and feel more empowered, increasing employee satisfaction and retention. | Strengthen Security Systematizing your warehouse management processes provides greater accountability, eliminates unauthorized access to critical data, and establishes an audit trail. | Enable Continuous Improvement Visibility and data help identify bottlenecks and improvements. For example, WMS software can run “what if” scenarios to determine how changes will impact operations. |

What Are the Features and Functionality of a Warehouse Management System?

A warehouse management system typically includes:

Warehouse Design

Inventory is placed in locations that make the most sense for workflow and to optimize storage space.

Inventory Tracking

Using barcode scanners and RFID technology, inventory is tracked so it can be easily found when needed.

Worker Performance

Staff performance is tracked and levels that are above or below standards are noted.

Picking, Packing, and Shipping

Ensures the correct product is picked, properly packed, and shipped to the correct customer on time.

Yard/Dock Management

Assists truck drivers to find the right location to unload, and provides other functions that optimize inbound and outbound logistics.

Reporting

Important information on the supply chain process is provided to managers for making improvements and planning for the future.

What Are the Key Types of Warehouse Management Systems?

There are different types of warehouse management system software available and ways of implementing it. There are different reasons why companies pick a type of WMS and implementation, so it is important to know the different types and which is best for your business based on your needs, budget, and IT infrastructure.

| Standalone | This type of system is designed to only handle the warehouse, but it can be combined with existing or future solutions, although it may not integrate and connect well with each other. It is the most basic of systems and only includes functions related to the movement of items within the warehouse. |

| Supply Chain Module | This system manages all aspects of the supply chain. It helps with vendor relationships, business processes, risk evaluation, and warehousing features. If you already have systems in place, you’ll want to avoid overlap with the supply chain module. If you plan to go in this direction, be sure to choose a system that can integrate well with your other software. |

| Integrated with ERP | This type of system/approach will be your most powerful choice and provides a more complete business management solution that integrates accounting and financials, customer relationship management, inventory management, and more. If you want to better connect all aspects of your business, streamline end-to-end processes, and see the benefit of growing and increasing your competitiveness with a single solution and source of data, this is a good solution. Warehouse management is offered in someERP systems, but not all, so be sure to look at only ERP systems that have that functionality. Also, some ERP vendors offer a WMS solution that is an add-on solution, sometimes provided by another 3rd party vendor, and some ERP vendors offer an ERP that has WMS fully integrated and built-in without needing an add-on solution. So be sure to look out for that as well. |

| On-premise | On-premise warehouse management systems require more internal resources to support and maintain. It is installed on the company’s native hardware and network. Many companies prefer this method as it gives them greater control. |

| Cloud-based | A cloud-based system does not require server hardware or synchronization with server hardware and networks as it is web-based. It is quicker to implement, easier to upgrade, simpler to use, and can scale with your business. |

What Is the Difference Between ERP and WMS?

WMS and ERP are two different software systems designed for different purposes. Warehouse Management System aims to simplify day-to-day warehousing operations, improve inventory accuracy and provide real-time visibility into warehousing activities. ERP (enterprise resource planning software) is a suite of business management solutions with multiple modules to manage every area of the organization. Most ERP systems include a Warehouse Management System module, but they are not all the same in the features they offer.

What Are the Benefits of WMS Integrated With ERP?

There are so many new technologies that are helping warehouses be more efficient, but they can only do so much without being connected to other parts of your business. When a warehouse management system is integrated, and even better fully built-in, with your ERP system, it further enhances business operations by connecting your whole organization. Having your WMS integrated with your ERP system provides additional business benefits that include:

Improved Visibility and Collaboration

Having all data and workflows housed and orchestrated in one system that is shared across the organization increases visibility throughout the company. It also integrates manufacturing and warehouse operations with core business functions like financials, customer service, logistics, and it improves coordination and collaboration.

Increased Accuracy

Eliminate manual entry and errors from data having to be re-entered because it is housed in one system of record and source of truth that other business functions and departments can access and share, avoiding the need for redundant data entry.

Better Decision Making

Real-time information from the warehouse provides insight into what is happening with inventory movement, customer orders, and overall scheduling and planning across the organization to help make informed decisions.

Smarter Sales and Customer Service

Provides the sales team with information on what is in stock and the lead times needed. It equips your customer service team with real-time status on customer orders and delivery timing so your business can make promises it can deliver upon.

Greater Agility

With a modern ERP system that is connected across the company, all departments are in sync and it is simpler to adjust business processes as needed when critical information is easily accessed and shared.

Faster Billing

Having shipment information processed immediately and sent to accounting allows for invoices to be sent quicker and payments to be received faster.

Track Productivity

With instant notification about where employees are with jobs, managers can ensure things are kept moving and they can track how well staff are performing.

How Do You Choose the Right Warehouse Management System?

Here are some key criteria to selecting the right WMS for your business:

Budget/ROI

Review the gains you will receive from a warehouse management system to help you determine your budget. You should receive a return on your investment in the form of:

- Improved processes and efficiency (doing more with fewer resources)

- Reduced costs from efficiency gains and better inventory management

- Better customer service for increased customer retention and revenue

- Improved accuracy resulting in less re-work and better decision making

- Increased visibility and traceability

- Increased productivity

- Better space utilization

Functionality

Look for systems that will perform the functions most important to your organization. Some of the essentials you’ll want are:

- Real-time inventory movement tracking

- Improved labor, equipment, and space utilization

- Greater picking, packing, and dispatch accuracy

- Better insight into operations

- Up-to-date technology that includes barcoding, RFID, serialization, mobility, etc.

Vendors

- Look into vendors and solutions that will best suit your needs and budget. Consider the following:

- Do they have expertise in your industry?

- Is their WMS an add-on or fully integrated with their ERP solution?

- How are upgrades handled?

- Are they responsive and helpful?

- Is customization needed?

- What is their training process?

- Create a Request for Information (RFI).

- Describe your business

- Outline your future business plans

- Explain what you hope to achieve with the WMS

- Provide information about your warehouse volume

- Request implementation time frames

- Ask how long before you will see ROI or time to value

- Ask about their company to include:

- History

- Functionality

- Similar customers

- Number of locations using their WMS

- Future development and product roadmap plans

- Support

- Successes

- Create a shortlist of vendors/solutions you prefer

- View demos, presentations, videos, etc. to understand how their solutions work

- Get and negotiate pricing proposals

- Check references

- Select your solution!

Get a Fully Integrated Warehouse Management System and ERP Solution With OptiProERP and SAP Business One

An all-in-one ERP solution for manufacturing and distribution